CO2 Emission Sources

CO2 Recycling

CRI commissioned the world’s largest CO₂ to methanol plant in 2022

Carbon Dioxide Capture and Use

Global net-zero targets are compelling industries worldwide to decarbonise their production processes. While some sectors can re-engineer their operations to reduce CO₂ emissions, this is more technically and financially challenging for other sectors, especially in sectors where carbon is an intrinsic part of the product and production process.

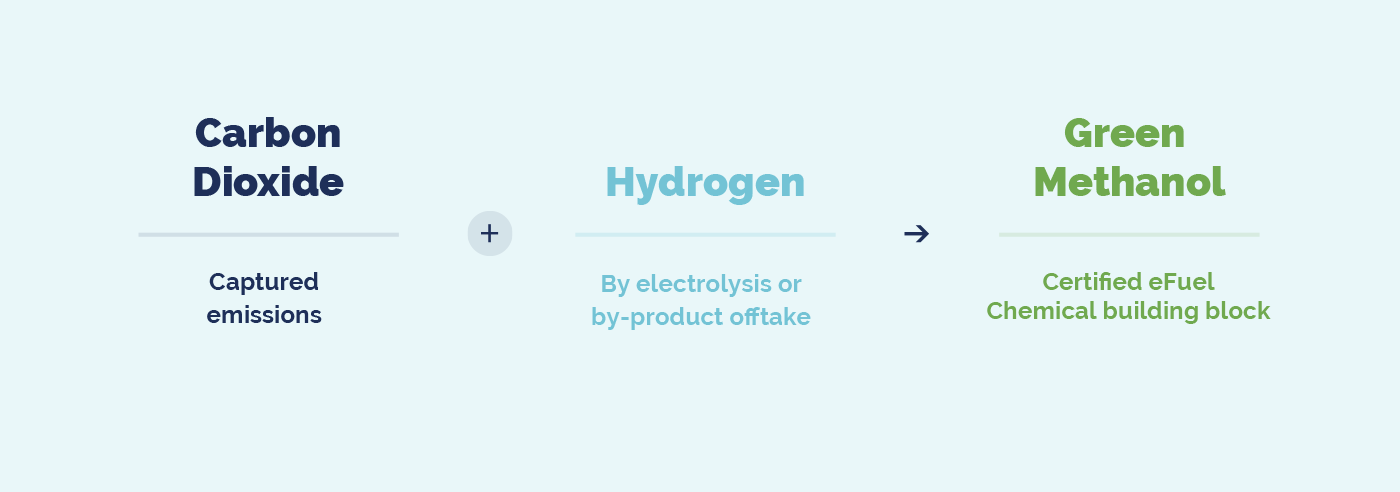

CO₂ recycling and effective carbon management, aided by renewable energy and hydrogen, can be the best practical option for managing the transition away from fossil-based carbon sources.

By partnering with CRI, emitters can capture CO₂ and convert it efficiently to eMethanol — a product that has an established market value and demand on a large, global scale. We recognise the distinct needs of different industries and have extensive experience in partnering with companies that emit CO₂, to develop sustainable solutions, right from early project development through to operation.

Industries where CO₂ recycling is a key part of the solution

In addition to reducing carbon emissions, the leading companies in these industries should also consider partnering with CO2 recycling companies to implement sustainable solutions and drive competitiveness.

Biogenic Carbon Dioxide

Biogenic CO₂ is released from biological processes such as fermentation as well as from biomass combustion. This CO₂ could be considered part of a natural carbon cycle, unlike fossil-based non-biogenic CO₂. Large industrial-scale plants, such as in pulp and paper, ethanol and biogas production, have the opportunity to implement Carbon Capture and Utilisation (CCU) technologies to find beneficial uses of their carbon dioxide and significantly reduce these emissions.

Geothermal & Direct Air Capture

Geothermal energy and direct air capture (DAC) are emerging sources of carbon. Although considered a green energy source, geothermal energy still emits some levels of CO₂. While geothermal power plants are currently not utilised as a major source of carbon, geothermal activity can be exploited to convert naturally emitted carbon dioxide into valuable products and fuels.

Direct Air Capture (DAC) is a technology that captures CO₂ directly from the atmosphere. Although it is still in development and undergoing upscaling, it is a promising technology for reducing CO₂ levels in the atmosphere and being a source of sustainable carbon for eFuels.

Chemicals & Plastics

The chemicals and plastics industries are both producers and consumers of carbon. Carbon dioxide is often emitted from burning fossil fuels or as a byproduct of the production process. Capturing and finding uses of carbon dioxide can create a circular economy within the chemical industry. When implemented alongside other green initiatives, such as direct electrification technologies, this approach can reduce the reliance on fossil-based fuels and chemical feedstocks, reducing emission levels. Sustainable practices are gaining traction in industry and it is forecasted that 50% of production facilities will have CCUs equipped by 2050*.

*Source: IEA report Net Zero by 2050

Waste Incineration

Waste incineration plants recover energy from waste that cannot be reused or recycled mechanically. Despite their benefits, these plants can generate significant amounts of CO₂ from burning mixed sources of waste. Integrating CCU technology, such as CRI’s, with incineration of waste, yields sizeable by-product value and delivers sustainability benefits for the operator.

Iron and Steel

Iron and steel production processes involve using fossil-fuel furnaces that release high levels of CO₂. Carbon Capture and Storage (CCS) and CCU technologies are pathways that can drastically reduce carbon footprint without the need to rebuild entire plants. For example, CRI has already implemented its Emissions-to-Liquids (ETL) technology in the iron and steel industry, turning residual gases from coking plants, burnt lime kilns and blast furnaces into methanol for use as a valuable chemical and fuel. CCU technologies are expected to become more commonplace with 37% of steel production facilities forecasted to have them fitted by 2050*.

*Source: IEA report The Iron and Steel Overview 2022

Cement

The cement industry is known to be hard-to-abate due to the inherent nature of cement production, its high-temperature heating requirements and the industry’s reliance on carbon-containing raw materials.

Accounting for about 8% of the world's CO₂ emissions, the cement industry is a major contributor to emission levels*. Deploying CCUs, alongside other near-term solutions such as improving plant efficiency, fuel switching and substituting low-carbon alternatives for traditional cement will be crucial to enabling higher levels of emission reductions.

*Source: IEA report Sustainablity 2024

Carbon Capture Utilisation and Storage

Our technology, know-how and project development experience have enabled CRI to realise some of the world’s largest CCUS projects. Capturing emissions from industries such as iron and steel and chemicals, we have recycled CO₂ to produce methanol, which is being used in chemicals and eFuels production.

We are working on many new projects across the world, bringing together companies with CO₂ emissions, renewable energy developers and methanol consumers to create a more sustainable society.

CRI Services

Project Feasibility & Conceptual Studies

ETL Technology

Project Technical Services

Lifetime Services

-

CO2 Emission Sources

-

Chemical Producers and Consumers

-

eFuels Producers and Consumers

-

Renewable Energy and Hydrogen Project Developers

Work with us

CO₂ Recycling | Renewable Energy Use | Renewable Methanol Production

proven at scale, with plants over 100,000 tonnes/year

technology with the best efficiency and flexibility for CO₂ recycling

expertise to realise projects